How to use food grade white silicone rubber for mold making is a great skill to use for many professions or crafting at home. Create the perfect silicone mold with Cast-a-Mold Platinum food-grade white silicone rubber, making it ideal for creating durable molds of any shape or size.

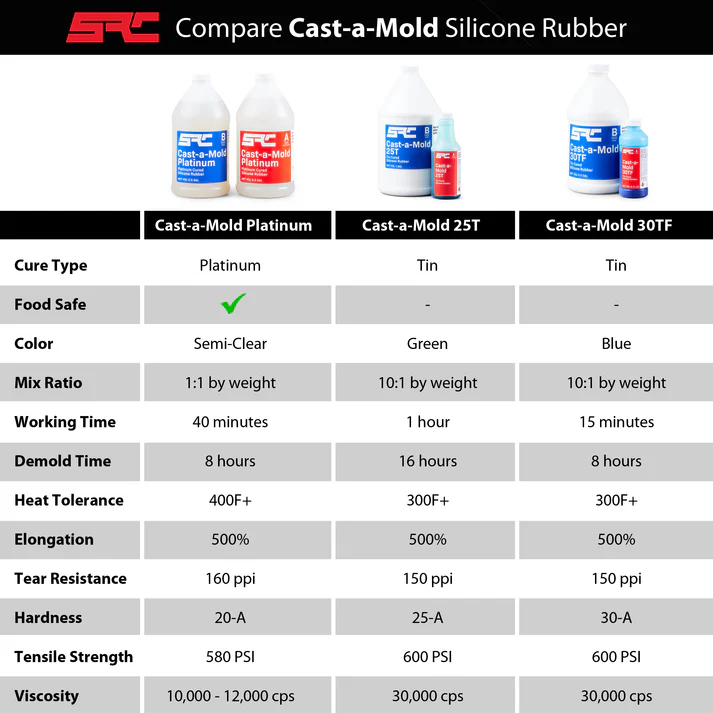

Cast-A-Mold Platinum is a versatile food grade white silicone rubber, platinum (addition) cured and is designed for a wide variety of mold-making applications.

It offers outstanding performance with its 1:1 mix ratio (by weight, not volume), it has a low viscosity, excellent tear strength, tensile strength, elongation, heat deflection. And a long library life (stored) for a silicone mold.

I/We promote transparency. This post or site may contain affiliate links. This means only if you make a purchase through these links, not just by clicking, I/we may earn a small commission at no extra cost to you.

As an Amazon Associate, I earn from qualifying purchases

Applications for Custom Molds.

Cast-a-Mold’s Platinum Food Grade white Silicone Rubber has uses that go far beyond just crafting custom resin molds .

It can be used to make translucent silicone molds for a variety of other projects, such as:

Casting candies and chocolates

Casting polyurethanes

Epoxy resin casting

Polyester resin casting

Cement

Cast Stone

Soap making

Candle making (and other wax applications)

Plaster

and many more!

FDA COMPLIANT.

Cast-A-Mold Platinum molding silicone is user-friendly and FDA-compliant, ensuring safe use in food-related applications. Its ability to cure at room temperature is another huge advantage, this eliminates the need for specialized equipment or degassing in vacuum chambers.

Tips, Tricks And a Few Notes Cast-A-Mold Platinum Food Grade Silicone Rubber:

If You Require a Super Fast Turn Around On a Mold.

Platinum-cured silicone rubber can be heat-accelerated. For instance, if you expose the mold to a temperature of 150°F (65°C), the curing time will be significantly reduced from 8 hours to just 30 minutes.

For more videos or product info follow this link here.

IMPORTANT.

For food applications, it is recommended to wash the cured mold with soap and warm water before using it, rinsing well to ensure cleanliness and hygienic standards.

Addition-cure silicone rubber may be affected by certain contaminants, which can lead to tackiness on the surface of the mold. To avoid this, it’s best to steer clear of materials like latex, sulfur-based clays, tin-cured silicone rubber, amines, nitriles, and organo-metallic salt-containing compounds.

If you’re uncertain about the compatibility of the model material being molded, it’s always advisable to conduct a small compatibility test beforehand.

Additionally, applying a clear acrylic lacquer or paint on the pattern or model can help prevent inhibition. However, this does not apply to polyurethane and latex being used or coated in this context.

Coloring Silicone.

The coloring of silicones can be very important in some industries that use it, especially if it is a silicone product they produce, like cookware.

In the crafting world or other production companies that use the product for their molds, it can be used to color code the group the mold belongs too. Which is very useful when you build up a stock of molds whether they are small or large.

Another use is to year date the year the mold was made, helping to track wear and tear and usage.

They are various forms of colorants available and nearly all are suitable for this grade of silicone. Liquid pigments, silicone-base pastes and gels, powered pigments and mica powders, the latter is more suitable for the finished product as it adds a sparkle to you silicones.

There are inks and dyes, but many don’t work and unless you have researched in detail stay away from them.

Release Agents.

When it comes to release agents, it is not needed for the production of most products. Allow an occasional spray with a silicone product helps with maintenance and longevity.

Some Production products do better with a release agent, silicone to silicone, epoxy resin, polyester and polyurethane resins. There might be others but I doubt you will come in to contact with them.

Now at the model making stage its best to air on the side of caution, a could procedure is to spay your model and casting/retaining frame with silicone release, brush it out with a good brush to get in to any awkward areas, as if you don’t the silicone will get in there and be such a pain to demold. And then mixing your silicone and just before you pour another light spray.

MIXING AND CURING:

Before use, be sure that Parts A and B are at room temperature and that all tools are ready for use. The surface and air temperatures should be above 60°F 16C) during application and for the entire curing period.

Read The Instructions

Always read any product labels or other instructions. Some products say by volume, but it is best to check the weight of the 2 containers that the material comes in, which should be on the label and if they are the same, it is a could practice to go by weight. Note, not all products are 1-1 or 50- 50%.

Set Yourself Up Correctly

Carefully weigh Part B and then part A in proper ratio into a clean mixing container. Accurate weighing is essential to obtain the optimum physical properties from the cured rubber.

Clean & Wax Containers

The best way is a clean container for the A & B and a 3rd larger one for mixing the 2 together in. A coat of molding wax applied inside your mixing containers will in most case let you peel off any remains after the material has set. Adding part A to the B is a good habit to get into.

Food Grade White Silicone Rubber Requires Mixing Slowly & Carefully

Mix thoroughly, scraping sides and bottom of the container. Making a good job of this will help with the final product and try not to add to much air into the mix to avoid any air pockets in the molds. If you decide to use a mixing drill, make sure the mixing paddle is suitable, and also use a clean piece of wood/spatula to scrape the sides occasionally.

If you follow these instructions and pour your silicone slowly, similar to the resins this should ensure an air bubble-free mold, take special care where there are protrusions on your model, working this way eliminates the need to deaerate/degas the product.

Food Grade White Silicone Rubber & Sizes Available.

If you need more information on this sized product click here 2 x 16oz =32OZ

For more information on this sized product click here 2 x 32oz = 64OZ

If you need more information on this sized product click here 2 x 1/2 Gallon =1 Gallon

And if you need more information on this sized product Click here 2 x 1 Gallon + 2 Gallon kit

And if you need more information on this sized product click here 2 X 5 Gallon=10 Gallon

Accessories For food Grade White Silicone Rubber

Colorants, putties and thinners are available too.

A Sample Of Customer Reviews

4.80 out of 5 Based on 20 reviews

Guy Perry

First time using this product and I find it more than exceeds my expectations.

Great product!

Tracey Mascaro

Love this silicone!

I love working with this food grade white silicone rubber, I make molds for my chocolates! The molds are perfect! I also use silicone thinning agents in the silicone for my 3D molds!

Ivy LePore

Food Grade White Silicone Rubber

I absolutely love this product! It cures to a perfect finish every time and clients love the end results! Thank you so much!

Edgar Partida

food grade white silicone rubber

Great product.

a href=”https://www.kqzyfj.com/click-101230848-15512741″ target=”_top”>Contact Us

We hope you find the information useful, but if you have any questions or need help, send us a message and we will respond in a timely manor. You do have to sign in and confirm these days to comply with government rules.

Author Rob