Part 2 of Polished Concrete Countertops

Step-by-Step Guide to Fabricate In A Workshop Your Polished Concrete Countertops

Creating polished concrete countertops by fabricating separately does have several of the same processes as pouring them in place. But different skills are needed. First, you’ll need a large, flat workbench big enough to accommodate the largest piece of your countertops – think of a garage or workshop.

As an Amazon Associate, I earn from qualifying purchases.

This post contains affiliate links. If you make a purchase through these links, I may earn a commission at no extra cost to you

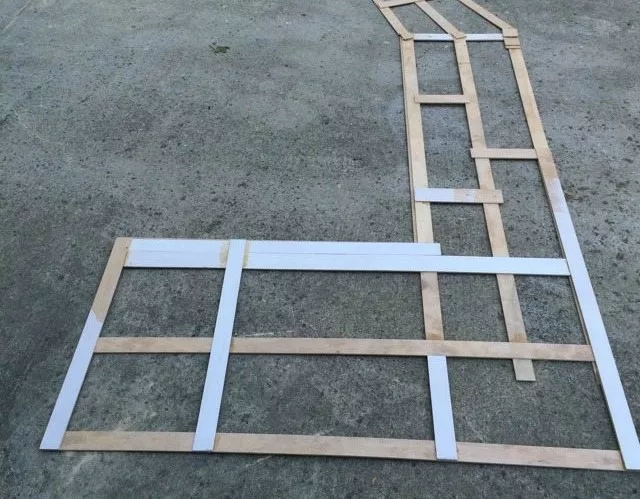

The next part is where many people might make mistakes, so take your time to go through this process. To be as accurate as possible it is best to make templates that reflect your soon-to-be-new polished concrete countertops. The best way and the way it is still done in the hard surface industry is to use 3-4″ wide strips of ¼” plywood, a glue gun and an indelible Sharpie pen. Take these strips and your glue gun and lay these strips to follow your walls and cabinets, Including any overhanging edges where your new tops will need to end and keep them flush where needed for the range, refrigerator or side walls.

Cut off your plywood strips as required as you go with a utility knife. Then glue all your pieces together at the corners or other joints. Sometimes you may need extra strips front to back for just a little extra strength when you move them to your workshop area. Then start marking which is the back, the front and “this way up” for the top. Continue to mark which parts must have the squared edges and which edges have your custom edge detail of choice.

Next mark where any cutouts for sinks etc need to be, this will help so much to avoid mistakes later. If you do have a particular large piece of kitchen top to make you may have to add an extra length of batten to allow you just to transport your template to your work area. Once everything is marked, and the glue is all set, it’s time to move your templates to your workbench which also doubles as your pour table, the table/bench top will be the surface of your new tops.

Copying Your Templates To Make Your Polished Concrete Countertops

Now it’s time to tip your templates upside down, but as you do this transfer all your makings to the other side too. Because now the top becomes the bottom, you are mirroring your templates. Hopefully, you have enough space on your workbench to accommodate all the pieces as it is best to just create the one mix. Now accurately draw around your templates so you are ready to start forming the sides to your molds.

Now it’s time to start positioning the sides to your molds. Start with your back edges and any square sides, and make sure whatever material you use is the right thickness for your tops. Depending on what your workbench is made of determines how you fix your edge details in place. Screws, glues or grab adhesives, but whatever you use keep the top edges clear for screeding and trowelling.

A very important part if you are using any inlaid edge details is to add the extra space/depth needed to accommodate them, they all vary so check them out and set these to finish on your template’s finished line. So now all your perimeters are in place, make sure they are 100% sealed to the surface of your workbench and any joints or corners are sealed too. This will stop any bleeding out of the mix.

Moving on to the next stage of your polished concrete countertops it’s time to form up any blockouts for the sinks, cooktops, taps etc. If your new sink(s) are going to be undermounts then all the edges will be visible so take care to use a suitable material to leave a good edge and make sure that the positions are correct. Before you move on to the next task check with your templates, still upside down that they fit exactly. If everything is good then move on to applying the release agent liberally. As you are going to be grinding your polished concrete countertops any slight imperfections will be taken out with the process.

Adding your Intended Embellishments to your Polished Concrete Countertops

Because with this method you are making your polished concrete countertops upside down, you can now place/sprinkle into position your colored aggregates, semi-precious stones, colored glass or other creative ideas, just nothing big or flat as it could leave voids in your concrete pour. Embedding items like stones, shells, or glass adds a personalized touch. You can lay these items in the mold before pouring the concrete. Once set and finished, these embedded objects create a unique, pattern or style that’s impossible to imitate with any other material.

Adding Reinforcing to your Polished Concrete Countertops

If there are any narrow strips of tops at places like the sinks and cooktops then adding some 3/8ths high tensile rebar might be a good idea, fiberglass rebar has too much flexural movement for this task, I would also use some of the same material if you are making extra long or large pieces. Keep all of these pre-bent and cut steels to one side until you have poured the bottom of your concrete this mix also requires additional concrete fibers for strength. Link to tops one

Now it’s time to follow the same procedures for mixing, curing, polishing and resin coating as the poured-in-place polished concrete countertops, with one major difference. The transporting and fixing in place of the tops. The plywood sub-base should be glued and screwed in place and levelled with a laser, ready to receive your new tops. Just double-check that nothing has changed, take your templates back in the original way up and double-check, before you put all the effort into moving them. If all is well have at least one extra person applying the adhesive to the laser levelled plywood as you come through with the team moving the pieces.

Gently set them in place, caulk as required and consider how your backsplashes can cover minor gaps and then continue with the fitting of all your appliances, if your tops have received any minor scratches either buff out any minor ones or worst case recoat with a thin layer of the 2 part resin.

Contact Us

We hope you find the information useful, but if you have any questions or need help, send us a message. You do have to sign in and confirm these days to comply with government rules. Sorry for the inconvenience.

Author Rob

I just read your second part on polished concrete countertops, and it was fantastic! I really loved how you detailed the benefits and maintenance tips—it makes the whole process feel more approachable. The photos you included really brought the ideas to life, too!

I’m curious, though—do you have any favorite color combinations or finishes that you think work best? And how do you see these countertops holding up over time compared to other materials? Thanks for sharing such an insightful article!

Hi Bob, Thank you for your comments. Favorite color combinations is a hard one to answer, we all have different tastes and preferences.

For me I am always in favor of mimicking the more semi-precious granite or marble slabs.

Rob