Plaster Moldings: A Historical Craft Evolved Through Modern Techniques

Plaster moldings have long been celebrated for their elegance and versatility, gracing buildings with intricate details and architectural beauty. This timeless craft dates back centuries, shaping ceilings, walls, and decorative elements in some of the most iconic structures around the world.

While plaster moldings have evolved significantly over time, their history and the artistry behind them remain fascinating. Let’s take a closer look at how these pieces were traditionally created, how modern techniques have revolutionized the process, and the role rubber molds now play in crafting these intricate designs.

As an Amazon Associate, I earn from qualifying purchases.

This post contains affiliate links. If you make a purchase through these links, I may earn a commission at no extra cost to you

The History of Plaster Moldings

Before the advent of rubber molds and modern production methods, plaster moldings were often created in situ (on-site). Artisans used plaster combs to build up the desired shape, layer by layer. These combs, carefully crafted to achieve specific profiles, allowed skilled craftsmen to shape ceiling crown moldings, cornices, and other architectural features directly onto walls or ceilings.

More intricate decorative elements, such as floral designs or ornate patterns, were painstakingly built up in place and carved by hand. This labor-intensive process required immense skill, patience, and artistry, as every detail had to be crafted manually to achieve the final design. The Picasso’s of plaster.

While this traditional method is now rare, it is still practiced in specialized projects, often in historic restorations or by highly skilled artisans, particularly those trained overseas. These specialists keep the tradition alive, working on buildings where authentic techniques are required to preserve historical integrity.

Modern Variations of the Technique

In some regions, similar methods are still used with a modern twist. For example, in the United States and countries like Mexico, plastering techniques using stucco/render are employed to coat polystyrene profiles in situ. This approach allows builders to create the appearance of high-quality plaster moldings at a lower cost. However, it is often reserved for areas where the moldings won’t be touched, as they produce a hollow sound when tapped.

This method has also been used as a cost-effective alternative to wet-cast textured stonework. While it may lack the density and durability of traditional plaster or stone, it can enhance the aesthetic of properties at a fraction of the cost.

Additionally, this technique is still employed in mold making to create original molding pieces. Straight or radius profiles can be combed with precision, producing a high-quality finish that is ready for the next step in the mold-making process. The quick turnaround time and smooth results make this an efficient choice for creating templates before the final rubber mold is produced.

The Rise of Rubber Molds in Plaster Crafting

Today, the introduction of rubber molds has revolutionized the production of plaster moldings. These molds allow for the creation of highly intricate designs with incredible consistency and precision. Rubber molds are particularly valued for their flexibility, making it easy to replicate fine details without risking damage to the mold or the casting.

In modern plaster molding production, rubber molds are typically paired with an outer support mold made from acrylic or fiberglass. This outer mold provides the rigidity and structure needed to maintain the shape of the rubber mold during the casting process.

Standard Sizes for Moldings:

- Larger molding pieces, such as ceiling crowns, are often cast in standard lengths of 8 feet.

- Smaller, more delicate pieces, such as intricate decorative trims, are typically cast in lengths of 4 feet or less.

Reinforcement for Durability

To ensure durability, plaster moldings are often reinforced with fine fiber matting. This matting is carefully spread into the piece after the first layer of plaster has been poured. This technique not only strengthens the molding but also ensures it can withstand handling and installation without compromising its intricate details.

Common Applications of Plaster Moldings

Modern plaster moldings have a wide range of applications, blending artistry with practicality. They are often used for:

- Ceiling and Wall Enhancements: Crown moldings, cornices, and decorative trims that add depth and elegance to any space.

- Architectural Elements: Columns, bases, and capitals that provide both structural and aesthetic appeal.

- Custom Designs: Bespoke pieces tailored to unique spaces or restoration projects.

Companies specializing in plaster moldings often offer an extensive range of designs, including columns with fluted or smooth finishes, ornate capitals, and intricate bases. These elements are designed to complement both traditional and contemporary interiors, making them a versatile choice for builders and designers.

How Plaster Moldings Are Made: Step-by-Step Process

Creating plaster moldings using modern techniques involves several key steps:

- Design and Template Creation:

- The process begins with a design, either sculpted by hand or created digitally. For simpler straight or radius pieces, plaster combing may still be used to shape the original.

- Rubber Mold Production:

- A flexible rubber mold is created from the original piece. This mold captures every fine detail, ensuring accuracy and consistency.

- Outer Mold Creation:

- To support the rubber mold, a rigid outer mold is made using acrylic or fiberglass. This ensures the rubber mold retains its shape during casting.

- Casting the Plaster:

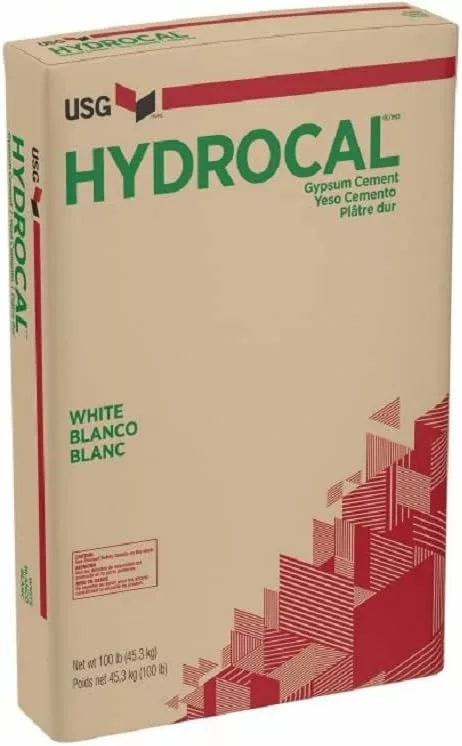

- Plaster is mixed to the desired consistency and poured into the mold. Fine fiber matting is added after the first layer to reinforce the piece.

- Finishing and Detailing:

- Once the plaster has cured, the piece is carefully removed from the mold. Any rough edges are sanded, and additional details may be carved or refined as needed.

- Installation and Final Touches:

- The finished moldings are installed and can be painted, sealed, or otherwise finished to match the design aesthetic, even in wood grain or marbleised finishes.

Why Learn the Craft of Plaster Moldings?

Mastering the art of plaster moldings offers numerous benefits:

- Creative Expression: Whether restoring historic spaces or designing new interiors, plaster moldings allow for artistic customization.

- Versatility: Suitable for a wide range of applications, from ornate decorations to simple trims.

- Timeless Appeal: Adds elegance and value to any space, blending seamlessly with various architectural styles.

- Minature Creations: This method is suitable for crafting projects and DIY projects inside an out.

For crafters, artisans, and DIY enthusiasts, learning these techniques opens the door to a rewarding and versatile craft.

Preserving a Tradition While Embracing Innovation

Plaster moldings represent a rich blend of history and innovation. From the traditional in situ methods of the past to the precision and efficiency of rubber molds today, this craft continues to evolve while honoring its roots.

By exploring and mastering these techniques, we not only preserve a timeless art form but also adapt it to meet the demands of modern design.

Join the Conversation

Have you worked with plaster moldings or used rubber molds in your projects? What challenges or successes have you encountered? Share your thoughts, tips, or questions—we’d love to hear from you!

Contact Us

We hope you find the information on plaster moldings useful, but if you have any questions or need help, send us a message. You do have to sign in and confirm these days to comply with government rules. Sorry for the inconvenience.

Author Rob

Ps. This is the company that taught me how to build this site and 3 others in 6 months, they keep their promises

This is a fascinating post on plaster moldings and their evolution as a historical craft! I love how you’ve delved into the history of plaster moldings, showcasing how this traditional art form has adapted over time while still maintaining its timeless appeal. From my experience, plaster moldings add a unique touch of elegance and craftsmanship to any space, and it’s great to see how the techniques have evolved to accommodate modern design trends while preserving their historical roots.

One question I have is: How do you recommend maintaining and preserving plaster moldings, especially in older homes where they may be more fragile? I’ve noticed that with age, plaster can sometimes crack or chip, and I’d love to know any tips or methods for keeping these beautiful details intact. Additionally, are there any modern materials or technologies being used in plaster molding today that offer the same aesthetic appeal but with greater durability?

Overall, this post provides a wonderful look at the art of plaster moldings, both historically and in modern times. It’s clear that this craft has a lot of value in preserving architectural beauty and adding character to spaces. Thanks for sharing these insightful details!

Thank you for your comments, Mr Cool.

I am glad you found the article informative, Regarding preserving or maintaining existing plaster moldings, most just require clean and normal decorating procedures.

Should you have a particular ornate piece that has suffered some damage then using a suitable adhesive filler may be more suitable. Each situation really needs to be evaluated to offer the perfect response.

Rob

This was such a cool read! It’s amazing how plaster moldings have evolved while still keeping that classic, timeless look. I never realized how much craftsmanship goes into the details, especially with restoring historical designs. Do you think modern techniques have improved durability, or do the traditional methods still hold up best?

Hi Randi,

Thank you for your comments. In answer to your question, I would say today’s products have improved the durability, not so much the methods.

Robby